- VMC Series Vertical Machining Center

- VTC Series Vertical CNC Lathe Machine

- TCK Series Slant Bed CNC Lathe

- WRC Series Wheel Repair CNC Lathe

- QK Series Large Bore Pipe Thread Lathe

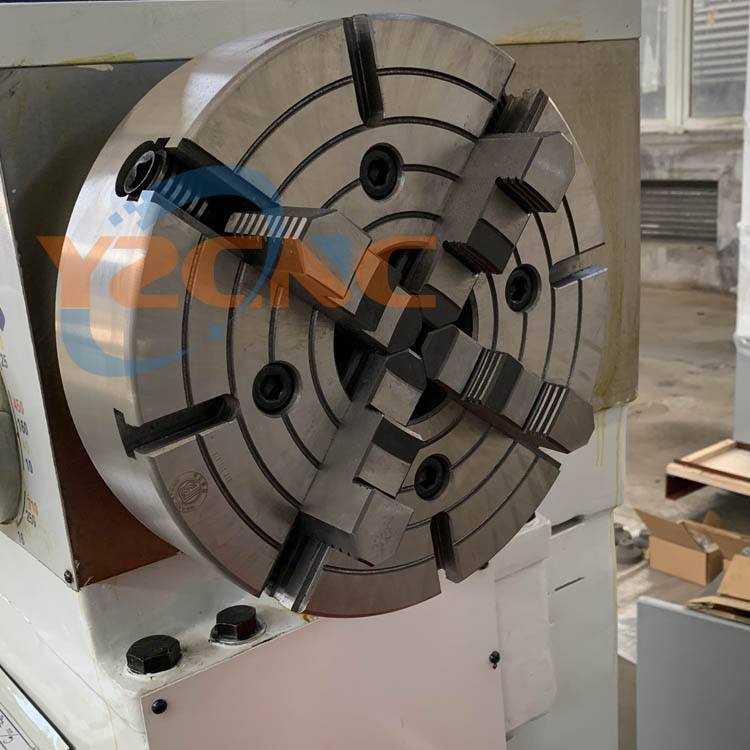

- CK Series Horizontal CNC Lathe Machine

- CK Series Heavy Duty CNC Lathe

- CA Series Universal Lathe

- Drilling and Milling Machine

- Sawing Machine

- Slotting Machine and Shape

- Radial Drilling Machine

GET A QUICK REQUESTS

Engine Lathe is a machine tool used in metalworking and woodworking applications to shape and cut materials. There are many different types of lathes, but the most common type is the engine lathe, also known as a metalworking lathe or a turning lathe.

The main uses of an engine lathe

The main uses of an engine lathe

The engine lathe is a versatile machine tool that can be used for a wide variety of metalworking and woodworking applications. Some of the main uses of an engine lathe include:

Turning: The en gine lathe is primarily used for turning operations, which involve removing material from the outside diameter of a workpiece to create a cylindrical shape. Turning is used to create parts such as shafts, cylinders, and tubes.

Facing: Facing is a machining operation that involves removing material from the end of a workpiece to create a flat surface. The engine lathe is commonly used for facing operations.

Drilling: The engine lathe can be used to drill holes in a workpiece. A drill bit is mounted on the tailstock and is rotated by the spindle. The workpiece is held in place by the headstock and is fed into the drill bit by moving the carriage.

Taper turning: Taper turning is a machining operation that involves creating a conical shape on the outside diameter of a workpiece. The engine lathe can be used to create tapered parts such as shafts and pins.

Thread cutting: The engine lathe can be used to cut threads on a workpiece. A cutting tool is mounted on the tool post and is fed into the workpiece at a specific angle to create the desired thread.

Knurling: Knurling is a machining operation that involves creating a pattern of small ridges on the outside diameter of a workpiece. The engine lathe can be used to create knurled parts such as handles and knobs.

Boring: Boring is a machining operation that involves enlarging an existing hole in a workpiece. The engine lathe can be used to bore holes in a workpiece using a boring bar that is mounted on the tool post.

CA6140 Engine Lathe Specification

| CA Manual lathe CA62 gap lathe | ||||||

| ITM | UNIT | CA6140 CA6240 | CA6150 CA6250 | CA6161 CA6261 | CA6166 CA6266 | CA6180 CA6280 |

| Max.swing over bed | mm | 400 | 500 | 610 | 660 | 800 |

| Max.swing over carriage | mm | 210 | 300 | 370 | 400 | 540 |

| Max.swing in gap | mm | 630 | 720 | 830 | 880 | 1020 |

| Max.swing length | mm | 210 | 210 | 210 | 210 | 210 |

| Effective gap length | mm | 750/1000/1500/2000/3000/4000 | ||||

| Width of lathe bed | mm | 400 | ||||

| Section of turning tool | mm | 25*25 | ||||

| Spindle speed | rpm | 16-1400 (24steps) | ||||

| Spindle bore | mm | 52/80/105 | ||||

| Spindle nose | 52bore: ISO(GB)C6 (80/105 bore:D8) | |||||

| Spindle taper | 52Bore:No.6 MT6 ,80Bore: 1:20 105Bore: 1:20 | |||||

| No.of feed | 64kinds | |||||

| Range of metric threads | mm | 1-192mm 44 kinds | ||||

| Range of inch threads | tpi | 1-24tpi 21kinds | ||||

| Range of module threads | 0.25-48module 39kinds | |||||

| Range of diametral threads | DP | 1-96DP 37kinds | ||||

| Max.tailstock travel | mm | 150mm | ||||

| Tailstock Diameter | mm | 75mm | ||||

| Taper of tailstock hole | MT5 | |||||

| Main motor | kw | 7.5 10HP | ||||

Related Products