VMC640 Vertical cnc machining center

VMC640 CNC Machining Center Various options for product configuration

- CNC system: optional GSK218M / Siemens 808 / Fanuc / Mitsubishi M80 /Syntec 22MA

- Tool magazine: optional funnel type tool magazine with 12/16/20 tool positions, Arm type tool magazine with 16/24

- Spindle speed: 8000/10000/15000rpm

- Turntable: four-axis five-axis

- Coolant through spindle

- Spindle oil cooling

- Chip conveyor

- VMC Series Vertical Machining Center

- VTC Series Vertical CNC Lathe Machine

- TCK Series Slant Bed CNC Lathe

- WRC Series Wheel Repair CNC Lathe

- QK Series Large Bore Pipe Thread Lathe

- CK Series Horizontal CNC Lathe Machine

- CK Series Heavy Duty CNC Lathe

- CA Series Universal Lathe

- Drilling and Milling Machine

- Sawing Machine

- Slotting Machine and Shape

- Radial Drilling Machine

GET A QUICK REQUESTS

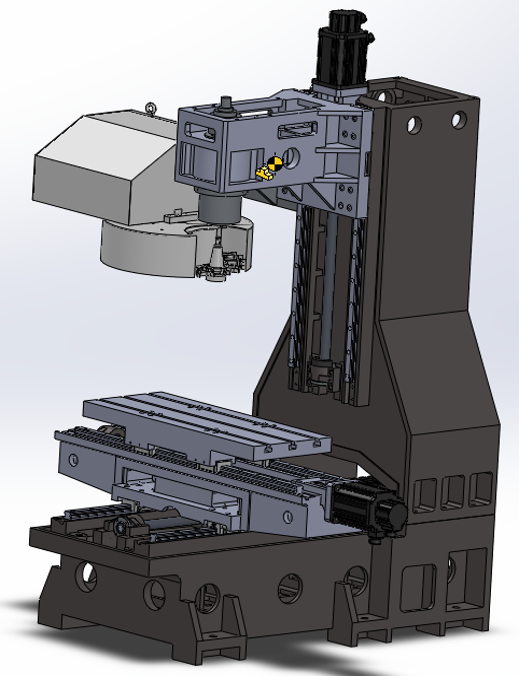

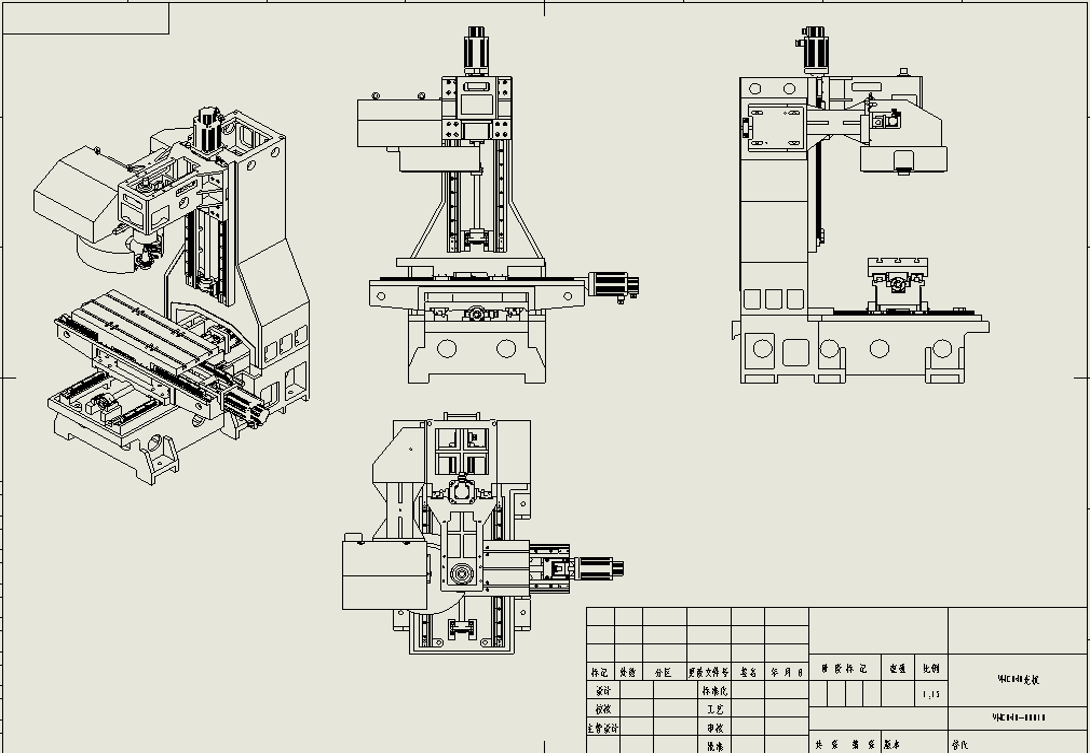

VMC Main feature

1.vmc640 Vertical cnc machining center overall framework is made of high grade casting iron with twice heat treatments and magnetic resonance. The natural aging relieves internal stress to ensure the lasting best rigidity and high precision.

2. The bed base assembling with the long-span coumn design increases the contact area between the column and the base.

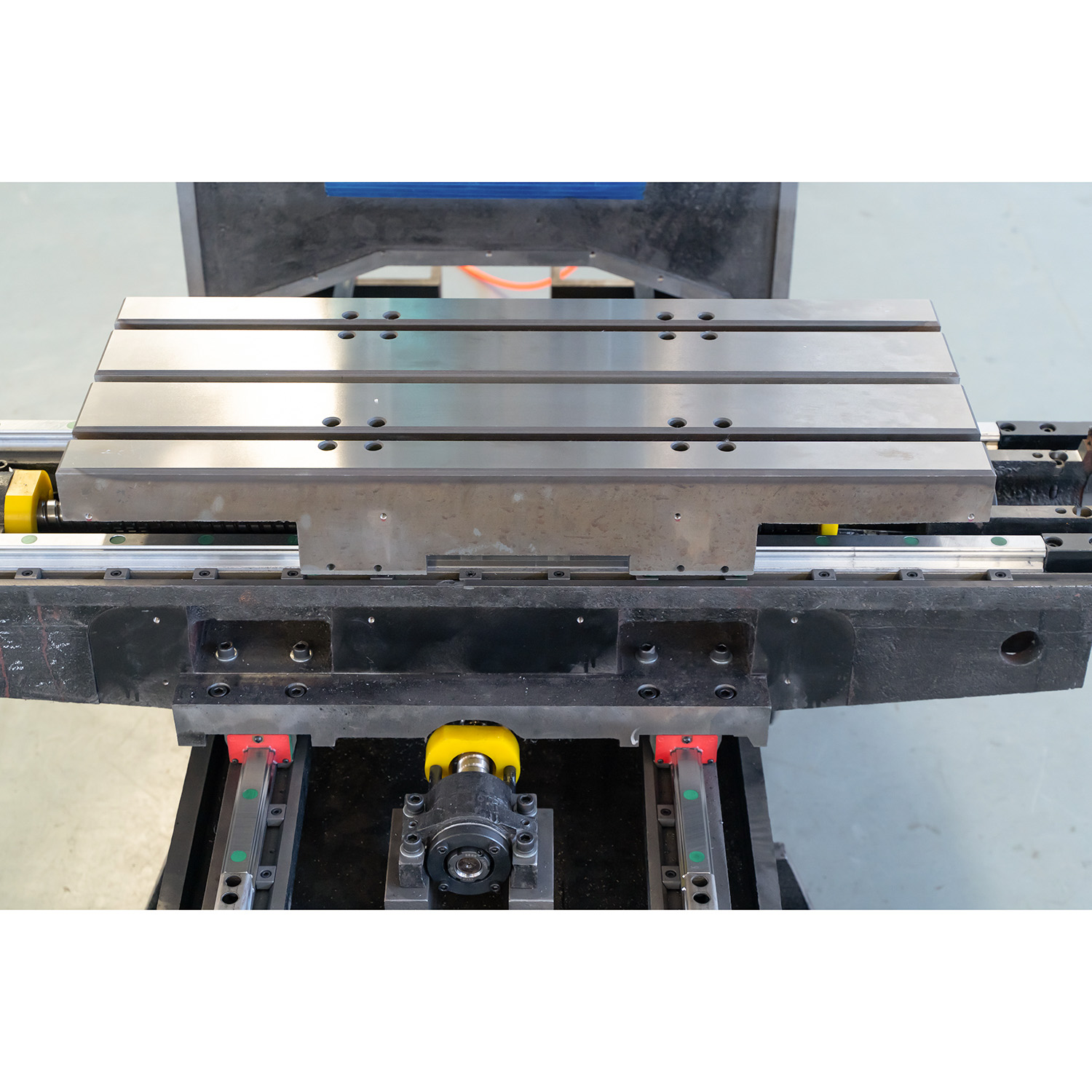

3. axis assembled with square guide rails, increase the processing strength and stock resistance significantly.

4. The spindle is assembled with high-power servo motor driving, high torque and wide range output.

5.The major outsourced components are all provided by foreign

6.PRECISION VERTICAL MACHINING CENTER

7.Using ATC24 manipulator automatic tool change magazine,quick changing tools time reaches 1.3seconds

8.Using original servo motor on 3 axes.Rapid feed speed can reach 48m/min.Motor base contact surface under artificial scraping griding, increase contact area and lasting stability of machine.

9.Using original Taiwan HIWIN OR PMI c3 class precision ball screw. Specialized japanese Nsk bearing with DB fitting method provides strong torque on machine processing. The ball screw proper pre-stretching treatment after installation effectively decreases thermal stretch to guarantee feed position accuracy and machining stability

10.Spindle head designed with double enclosed structure and increasing slider assembling base distance, effectively guarantee the machine processing strength.

VMC640 cnc machining center

| ITEM | UNIT | VMC640 | ||

| Table | Size | MM | 800 X 320 | |

| Max load | KGS | 400 | ||

| T-Slot size | MM | 16 X 3 | ||

| Working area | X-axis | MM | 600 | |

| Y-axis | MM | 400 | ||

| Z-axis | MM | 500 | ||

| Spindle nose to table | MM | 130-630 | ||

| Spindle center to z axis guide surface | MM | 430 | ||

| spindle | Spindle taper | BT40-120 | ||

| Spindle speed | RPM | 8000 | ||

| pindle motor power | KW | 5.5 | ||

| Feed | Fast feed | X | M/MIN | 24 |

| Y | M/MIN | 24 | ||

| Z | M/MIN | 20 | ||

| cutting speed | MM/MIN | 1-1000 | ||

| feed motor power | X | N | 6 | |

| Y | N | 7.5 | ||

| Z | N | 15nm | ||

| Capacity | Types tool changers | Funnel type tool changer/Arm type tool changer ATC | ||

| Capacity of tools | 12/16 | |||

| Tool change time | S | 8/2.5 | ||

| Accuracy | Position Accuracy | MM | ±0.006 | |

| Repeatability | MM | 0.008 | ||

| Size | machine size | MM | 2200 X 1900 X 2500 | |

| Packing dimension | MM | 2400 X 2100 X 2300 | ||

| weight | Kgs | 2800 | ||

Related Products