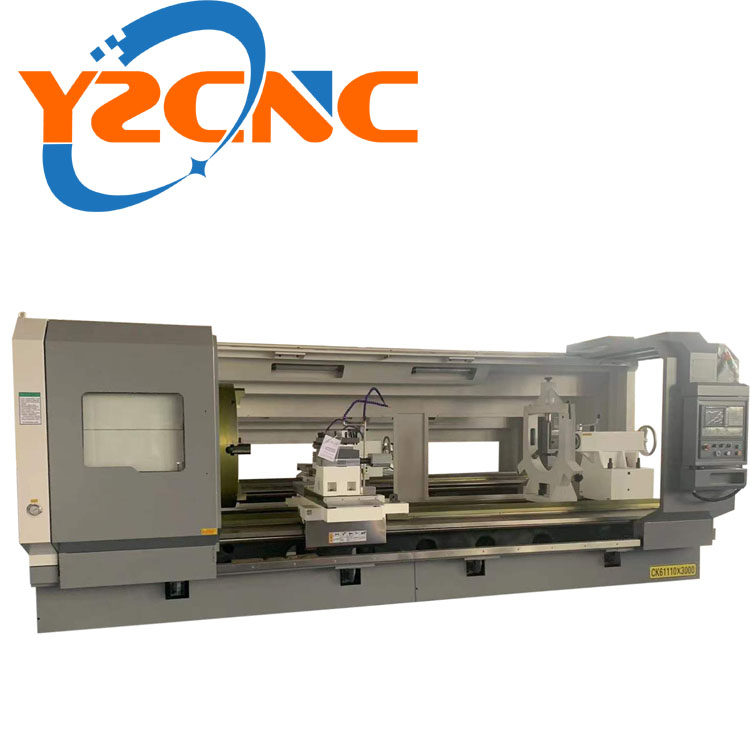

CK0640 Flat bed small cnc lathe structures are designed, developed, and manufactured by the requirements of international standards. Small cnc lathe has good precision and stability, strong rigidity, small thermal deformation of the independent spindle, good precision retention, and excellent maintenance-free characteristics, suitable for heavy cutting. The machine concept has reached the international advanced level. Advanced structural design and perfect supply measures make the machine tool have high reliability and long-term high precision retention.

CK0640 Flat bed small cnc lathe structures are designed, developed, and manufactured by the requirements of international standards. Small cnc lathe has good precision and stability, strong rigidity, small thermal deformation of the independent spindle, good precision retention, and excellent maintenance-free characteristics, suitable for heavy cutting. The machine concept has reached the international advanced level. Advanced structural design and perfect supply measures make the machine tool have high reliability and long-term high precision retention.

CK0640 Small Cnc Lathe product advantages

- Fully enclosed protection design, good waterproof. Compact layout, saving space,

- Perfect match of automatic transmission and independent spindle

- Stable precision, high torque, high rigidity, good vibration resistance, and high processing efficiency.

- Modular design, independent maintenance-free spindle structure has the characteristics of fast start and stop, stable, efficient, and high-precision processing, etc.

- There are two types of spindles: independent spindle and gearbox. The independent spindle has the characteristics of high speed and high precision. Gearbox with high torque, heavy cutting, etc.

- High rigidity tailstock design

CK0640 Small Cnc Lathe Specification

| ITM | unit | CK0640 | CK6132 | CK6432 | CK6136A/CK6140A | CK6136FL/CK6140FL | CK6146 | |

| Machining Range | Max. Swing over bed | MM | 260 | 350 | 360 | 360/400 | 360/400 | 460 |

| Max. Swing over cross slide | MM | 100 | 180 | 180 | 220 | 220 | 230 | |

| Max. work length | Mm | 200 | 400 | 450 | 600/850 | 600/850/1350 | 750 | |

| Max. Z axis Travel | MM | 280 | 450 | 500 | 750/1000 | 750/1000 1500 | 1000 | |

| Max. X axis Travel | MM | 280 gang Gang tool | 280 Gang tool | 290 Gang tool | 250 | 250 | 250 | |

| Spindle | Spindle bore | MM | 48/60/80 | 48 | 60 | 60 | 52 | 66 |

| Spindle nose | A2-5 | A2-5 | A2-6 | A2-6 | A2-6 | A2-6 | ||

| Spindle speed range | RPM | 50-2500 | 100-2500 | 100-2500 | 100-2500

| 100-2500 | 100-2500 | |

| 100-750,500-1500

| 90-500/400-800/600-1700 | |||||||

| Spindle type | Independent spindle | Independent spindle Manual 2 steps | Manual 3steps 独Independent spindle | |||||

| Chuck | MM | Pneumatic chuck/manual 3 jaws 160mm | 200mm manual 3 jaws 200mm | |||||

| Lathe bed | Bed width | MM | 260 | 260 | 260 | 330 | 360 | 380 |

| Feed | x/z fast feed | Mm/ min | 6000/8000 | |||||

| x/z cutting travel speed | Mm/ min | 1-6000 | ||||||

| Tool Turret | Number of tool turret | gang type tool post

| 4/6/8 turret | 4/6/8turret | 4/6/8turret | |||

| Tool shank type | MM | 16*16/20*20 | 20*20 | 20*20 | 25*25 | |||

| Working accuracy | Positioning accuracy | MM | X≤0.010 Z ≤0.015 | |||||

| Repeatability Positioning accuracy | MM | X≤0.0075 Z ≤0.010 | ||||||

| Min. unit set | MM | 0.001 | ||||||

| roundness | MM | ≤0.007 | ||||||

| Diameter uniformity | MM | ≤0.03 (length 300) | ||||||

| Flatness | MM | ≤0.02 (Diameter 300) | ||||||

| Surface Roughness (Steel) | Ra1.6um | |||||||

| Tailstock | Dia. of tailstock sleeve | MM | 55 | 60 | 60 | 60 | 60 | 60 |

| Tailstock sleeve taper | MT4 | MT4 | MT4 | MT4 | MT4 | MT5 | ||

| Max. Tailstock sleeve travel | MM | 150 | 100 | 120 | 140 | 140 | 140 | |

| Motor | Spindle drive motor power | KW | 4 | 4 | 4 | 5.5 | 5.5 | 5.5 |

| Coolant pump power | W | 90 | 90 | 120 | 120 | 120 | 120 | |

| size | L W H | MM | 1600X1200X1550 | 2050X1500X1650 | 1650X1400X1550 | 2150X1400X1600 | 2200X1500X1750 | 2150X1400X1660 |

| weight | 800KG | 1.2T | 1.2T | 1.7T | 1.6T | 1.7T | ||