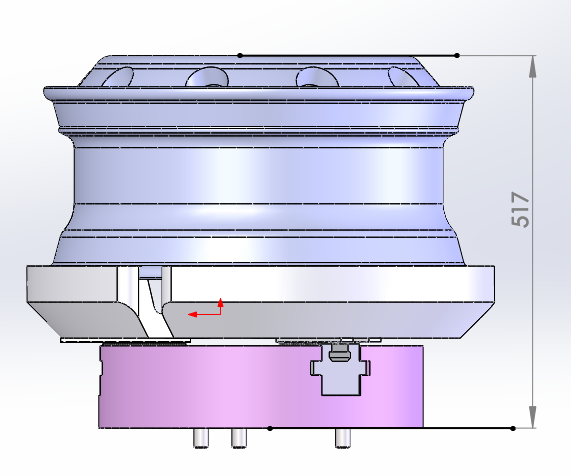

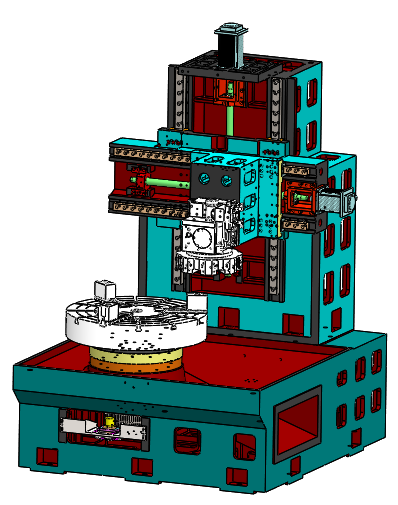

The spindle of the vertical lathe is vertical and has a circular table on which the workpiece is mounted. As shown in the figure “Vertical Lathe”, is the outline drawing of a single-column vertical lathe. Since the workbench is in a horizontal position, it is more convenient to align and clamp the workpiece, and the gravity of the workpiece and the workbench is borne by the bed guide rail or thrust bearing, and the spindle does not bend. Therefore, the vertical lathe is suitable for processing larger disks and large and short sleeve parts.

Single-column vertical lathe

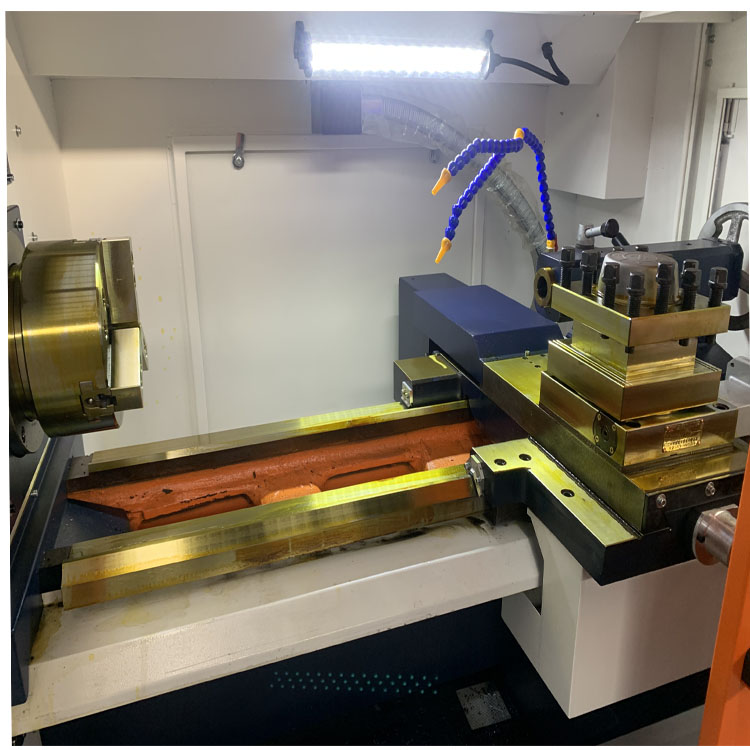

The single-column vertical lathe is a universal lathe in the vertical lathe series. It is suitable for turning, drilling, reaming, boring and other processing. It is worth mentioning that it is specially designed for the ball plate processing of steel ball equipment, and is also widely applicable to the processing of various disc-shaped parts

Vertical lathe Horizontal lathe

Vertical lathe and Horizontal difference?

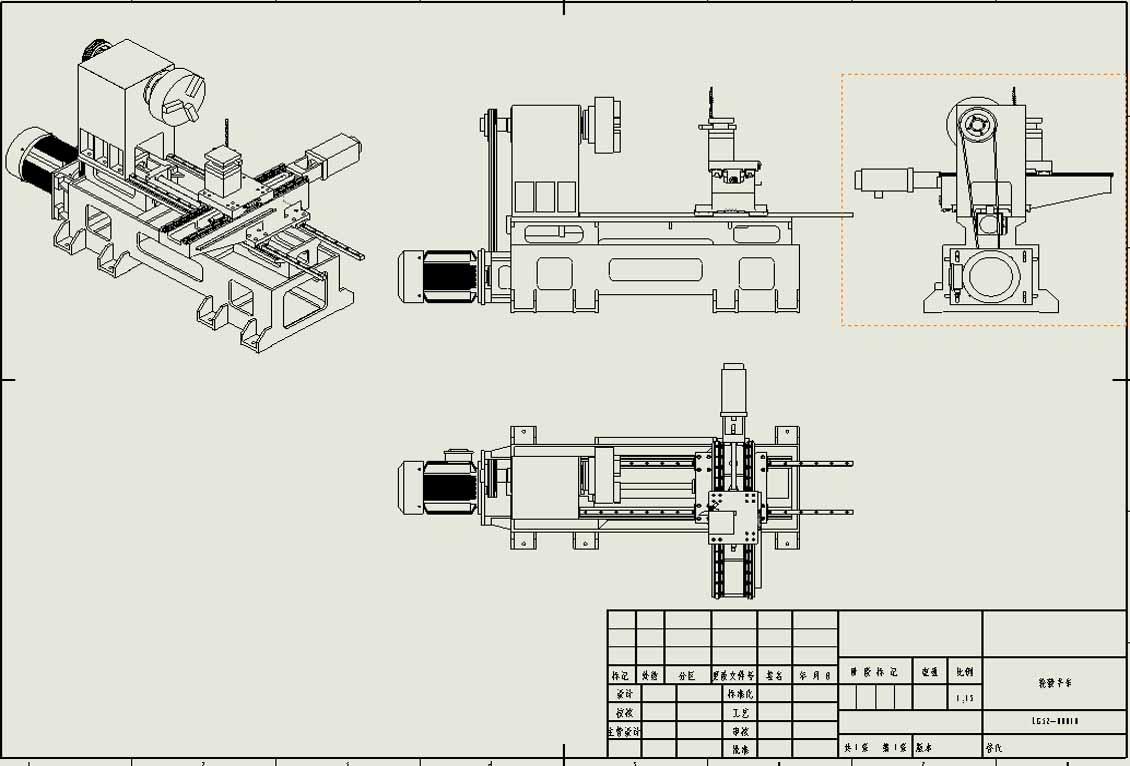

The difference between a vertical lathe and a horizontal lathe is that its main shaft is vertical, which is equivalent to standing an ordinary lathe upright. Due to the horizontal position of its table, it is suitable for machining heavy parts with large diameters and short lengths.

The difference between a vertical lathe and a horizontal lathe is that its main shaft is vertical, which is equivalent to standing an ordinary lathe upright. Due to the horizontal position of its table, it is suitable for machining heavy parts with large diameters and short lengths.

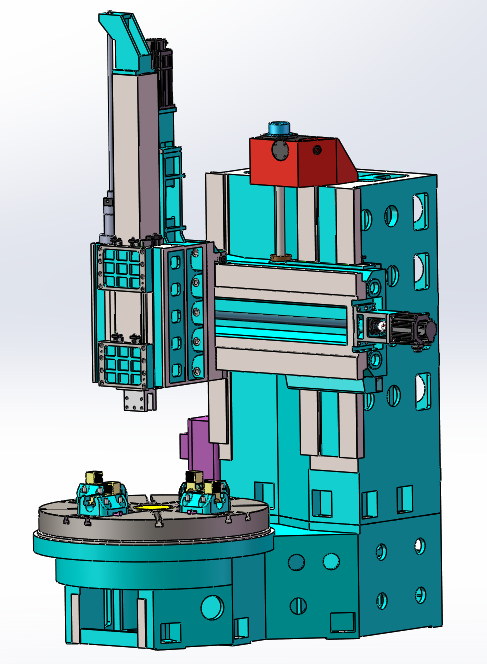

The vertical lathe can process inner and outer cylinders, conical surfaces, end planes, grooves, chamfers, etc., and the clamping and calibration of workpieces are more convenient.

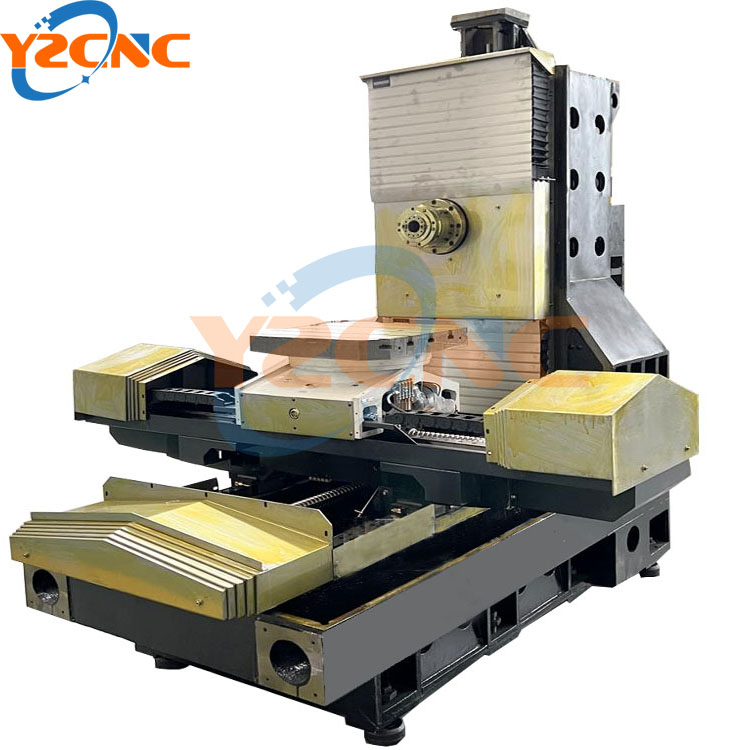

The vertical tool holder on the vertical lathe can move along the beam guide rail and the tool holder seat guide rail for horizontal or longitudinal feed. The tool holder seat can be deflected at a certain angle for oblique feeding. The side tool holder can move up and down along the guide rail of the column, and can also move left and right along the sliding seat of the tool holder to realize longitudinal or horizontal feeding.

Introduction of vertical lathe

Vertical lathes are large-scale mechanical equipment used to process large and heavy workpieces with large radial dimensions and relatively small axial dimensions and complex shapes. Such as the cylindrical surface, end surface, conical surface, cylindrical hole, conical hole, etc. of various discs, wheels, and sleeves. It can also be used for threading, spherical turning, profiling, milling, and grinding with the help of additional devices. Compared with the horizontal lathe, the workpiece is clamped inside the clamp decoration of the horizontal lathe. On the vertical lathe, the spindle axis is arranged vertically, and the table top is in the horizontal plane, so the clamping and alignment of the workpiece are more convenient. This layout reduces the load on the spindle and bearings, so the vertical lathe can maintain working accuracy for a long time

Matters needing attention in the operation process of vertical lathe

1. The rough surface of the workpiece is not allowed to be placed directly on the work surface, and it should be supported by a pad iron or screw top; it is strictly forbidden to use the work surface to perform other operations such as correcting the workpiece by hammering, welding the workpiece, etc.

1. The rough surface of the workpiece is not allowed to be placed directly on the work surface, and it should be supported by a pad iron or screw top; it is strictly forbidden to use the work surface to perform other operations such as correcting the workpiece by hammering, welding the workpiece, etc.

2. When aligning the workpiece, the worktable can only be rotated at a low speed to align, and high-speed alignment is not allowed.

3. When starting and stopping the workbench, the handle of the workbench can only be turned by hand, and pedals are strictly prohibited.

4. When the worktable is rotating, it is not allowed to do the lifting of the beam and the rapid movement of the tool holder.

5. When moving the beam, the clamping device must be loosened first, and it should be clamped immediately after moving. After the beam is lowered each time, it should be raised a little to eliminate the gap between the screw and the nut.

6. It is not allowed to carry out gravity cutting when the ram of the straight tool holder and the side tool holder is extended for a long time; when using a vertical tool holder for processing, especially when doing gravity cutting, the beam should be lowered as close as possible to the work position.

7. When performing intermittent cutting, the amount of feed and the rotational speed of the worktable should be appropriately reduced.

8. When changing gears, the joystick must be pushed to the specified position. If the gears are not well meshed, they should be adjusted by micro-movement after work, and forced operation is not allowed

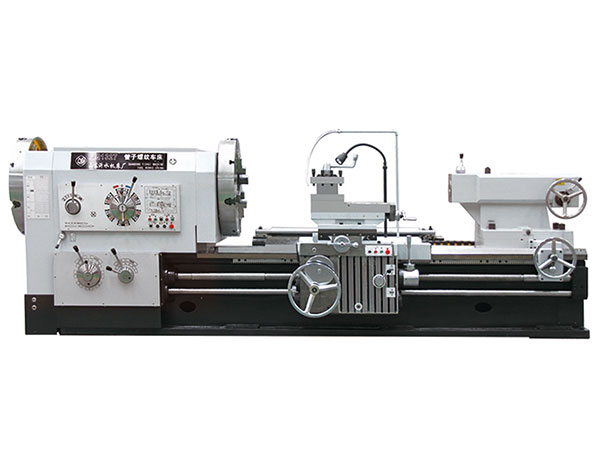

The difference between Manual lathe, CNC lathes, and vertical lathes

Ordinary lathes are driven by gears and ordinary screw nuts. Due to the gaps between the kinematic pairs and the inaccurate manual operation, the repeatability is low. When measuring with ordinary lathes, it is necessary to stop and measure manually, the measurement error is relatively large, and the efficiency is low. It is suitable for small batches, low precision requirements, and zero-moving parts. Its investment is lower than that of CNC, but it requires higher operational skills of workers, so the wage level is high. The scrap rate and productivity of low-skilled workers can give you headaches.

The CNC lathe is driven by a stepping motor to drive the ball screw. Since the ball screw can have interference, the transmission has no gap, and the accuracy is mainly guaranteed by the machine tool itself and the program. It can be measured automatically during processing, and can automatically compensate for errors caused by tool wear and other reasons. Therefore, the processing quality is good and the precision is stable. It can also use the method of programming to turn parts with complex shapes that are difficult to process with ordinary lathes. Suitable for parts with high precision, large batches, and, complex shapes. But small batches work well too. Its maintenance cost is higher than that of ordinary lathes.

The CNC lathe is driven by a stepping motor to drive the ball screw. Since the ball screw can have interference, the transmission has no gap, and the accuracy is mainly guaranteed by the machine tool itself and the program. It can be measured automatically during processing, and can automatically compensate for errors caused by tool wear and other reasons. Therefore, the processing quality is good and the precision is stable. It can also use the method of programming to turn parts with complex shapes that are difficult to process with ordinary lathes. Suitable for parts with high precision, large batches, and, complex shapes. But small batches work well too. Its maintenance cost is higher than that of ordinary lathes.

The vertical lathe is mainly used for large pieces, and its main shaft is vertical. The vertical lathe also has numerical control. Due to the increasing shortage of high-tech talents, newly established enterprises mostly use numerical control to improve productivity and product quality and reduce scrap rates and costs.

Maintenance of vertical lathe

1. The use environment of vertical lathe

The vertical lathe is best placed in a constant temperature environment and away from equipment with large vibrations (such as punching machines) and equipment with electromagnetic interference.

2. power requirements

3. The vertical lathe should have operating procedures for regular maintenance and maintenance, and pay attention to record and protecting the site when there is a failure.

vertical lathe

4. Vertical lathes should not be stored for a long time

5. Pay attention to the training and deployment of operators and maintenance personnel

Maintenance of vertical lathe system

1. Strictly abide by the operating procedures and daily maintenance system.

2. Prevent dust from entering the electronic control device Floating dust and metal powder can easily cause a decrease in the insulation resistance between electrical components, failing or even damage to the components.

3. Regularly clean the heat dissipation and ventilation system of the electric control cabinet.

Manufacturers of vertical lathes in China

1. Yuzhuo Machinery( YZCNC Lathe) Company Limited is a professional manufacturer engaged in the research, development, production, sale, and service of Wheel repair C N C lathe, Vertical C N C Lathe, Slant Bed C N C lathe, Universal lathe, Pipe threading C N C Lathe, C N C milling machine and C N C machining center. Generally, quotations will be delivered within 24 hours after submitting RFQs with clear information. You can get product price, freight, tax, delivery date, best processing method and transportation method, etc. In addition, we have obtained a C E certificate. Selling well in many cities and provinces around China, our products are also exported to clients in such countries and regions as the UK, Ireland, Poland, Germany, Italy, Spain, France, Russia, Ukraine, Sweden, Netherlands, Belgium, Switzerland, US, Canada, Mexico, Argentina, Colombia, Australia, Saudi Arabia, UAE, Egypt, South Arica, Jordan, Korea, Malaysia, Kazakhstan, Uzbekistan, Philippines, Singapore. We also welcome O E M and O D M orders. There are many choices available for you but choosing us is a good start. We are dedicated to providing customers with the best, high-value-added machines. We sincerely wish to establish a win-win long-term relationship with you. If you want to know more, please feel free to contact us. We will reply to you as soon as possible. Have a great day! Thank you for your time.

2. Taizhuo Machinery Co., LTD.

3. Shenyang CNC Industrial Park has completed the relocation and realized professional reorganization. Through professional reorganization, business process reengineering, and informatization construction, Shenyang CNC Machine Tool Industrial Park will become a modern and large-scale CNC machine tool manufacturing base.

4. DMTG’s main products are CNC flexible combined machine tools and automatic production lines, intelligent manufacturing units and production lines, five-axis linkage vertical machining centers, horizontal machining centers, vertical turning-milling compound machining centers, horizontal turning-milling compound machining centers, high-speed, Precision machining center, high-speed precision turning center. Industrial robots, CNC systems, CNC tool magazines, CNC tool tables, ball screws, linear guides, electric spindles and high-speed spindles, and other products. Through the introduction of technology and independent innovation, Dalian Machine Tool has maintained the leading technology of product level. More than 60 major scientific and technological patents such as precision machining of key parts of automobile engines and research and development of functional components of CNC machine tools. Dalian Machine Tool provides high-quality machine tools for China’s automobile, rail transit, construction machinery, petroleum machinery, mining, and metallurgy industries.

5. Qinchuan Machine Tool Group Co., Ltd. has core technologies such as gear grinders, cylindrical grinders, high-speed hobbing machines, compound gear tools, broaching technology and equipment, and can provide users with a complete set of process equipment solutions from drawings to workpieces, forming a unique “precision, compound, Special, Large” product positioning advantage, marching into the middle and high end of the global precision machine tool industry chain.