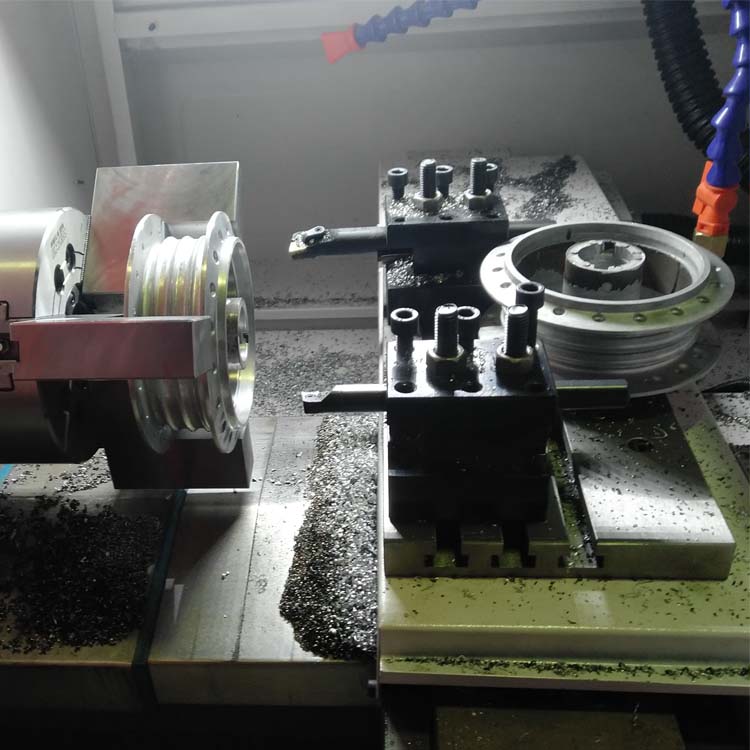

CK6132 Cnc lathe

Free Instant Quote within 8 Hours

Generally, quotations will be delivered in 8 hours after submitting RFQs with clear information. You can get product price, freight, tax, delivery date, best processing method and transportation method, etc.

25+ Years in Lathes Manufacturing Online

Having carried out rapid prototyping and custom parts machining online for 20 years, our engineers have built up rich experience. We can handle all types of projects.

Factory Direct Lathe Price & CE And SGS Quality Assurance

Factory lower price and fast lead-time. CE Certified Quality.

10000+Machine Tool Delivered

Over 10K Cnc milling machine cnc lathes cnc turning center and Slant bed cnc lathe have been sent to our customers worldwide in the past 15 years, and we have received countless positive comments.

- VMC Series Vertical Machining Center

- VTC Series Vertical CNC Lathe Machine

- TCK Series Slant Bed CNC Lathe

- WRC Series Wheel Repair CNC Lathe

- QK Series Large Bore Pipe Thread Lathe

- CK Series Horizontal CNC Lathe Machine

- CK Series Heavy Duty CNC Lathe

- CA Series Universal Lathe

- Drilling and Milling Machine

- Sawing Machine

- Slotting Machine and Shape

- Radial Drilling Machine

GET A QUICK REQUESTS

CK6132 Cnc lathe structures are designed, developed, and manufactured by the requirements of international standards. The whole machine has good precision and stability, strong rigidity, small thermal deformation of the independent spindle, good precision retention, and excellent maintenance-free characteristics, suitable for heavy cutting. The machine concept has reached the international advanced level. Advanced structural design and perfect supply measures make the machine tool have high reliability and long-term high precision retention.

CK6132 Cnc lathe structures are designed, developed, and manufactured by the requirements of international standards. The whole machine has good precision and stability, strong rigidity, small thermal deformation of the independent spindle, good precision retention, and excellent maintenance-free characteristics, suitable for heavy cutting. The machine concept has reached the international advanced level. Advanced structural design and perfect supply measures make the machine tool have high reliability and long-term high precision retention.

CK6132 Cnc lathe product advantages

1. Fully enclosed protection design, good waterproof. Compact layout, saving space,,

2. Perfect match of automatic transmission and independent spindle

3. Stable precision, high torque, high rigidity, good vibration resistance and high processing efficiency.

4. Modular design, independent maintenance-free spindle structure has the characteristics of fast start and stop, stable, efficient and high-precision processing, etc.

5. There are two types of spindles: independent spindle and gear box. The independent spindle has the characteristics of high speed and high precision. Gearbox with high torque, heavy cutting, etc.

6. High rigidity tailstock design

CK6132 Cnc Lathe Multiple options to meet all-round needs of users

1.Can be configured Manual chuck Hydraulic chuck Hydraulic tailstock Pneumatic chuck Pneumatic tailstock

2. 4/6/8 station turrets

3.GSK Siemens / Fanuc / Syntec/ KND

4.Square cutting power head .

5.Equipped with automatic bar feeder (both oil bath type and servo feeder)

CK6132 Cnc Lathe Specification

| ITM | unit | CK6132 | |

| Machining Range | Max. Swing over bed | MM | 350 |

| Max. Swing over cross slide | MM | 180 | |

| Max. work length | Mm | 400 | |

| Max. Z axis Travel | MM | 450 | |

| Max. X axis Travel | MM | 280 Gang tool | |

| Spindle | Spindle bore | MM | 48 |

| Spindle nose | A2-5 | ||

| Spindle speed range | RPM | 100-2500 | |

| Spindle type | Independent spindle | ||

| Feed | x/z fast feed | Mm/ min | 6000/8000 |

| x/z cutting travel speed | Mm/ min | 1-6000 | |

| Tool Turret | Number of tool turret | gang type tool post

| |

| Tool shank type | MM | 16*16/20*20 | |

| Working accuracy | Positioning accuracy | MM | X≤0.010 Z ≤0.015 |

| Repeatability Positioning accuracy | MM | X≤0.0075 Z ≤0.010 | |

| Min. unit set | MM | 0.001 | |

| roundness | MM | ≤0.007 | |

| Diameter uniformity | MM | ≤0.03 (length 300) | |

| Flatness | MM | ≤0.02 (Diameter 300) | |

| Surface Roughness (Steel) | Ra1.6um | ||

| Tailstock | Dia. of tailstock sleeve | MM | 60 |

| Tailstock sleeve taper | MT4 | ||

| Max. Tailstock sleeve travel | MM | 100 | |

| Motor | Spindle drive motor power | KW | 4 |

| Coolant pump power | W | 90 | |

| size | L W H | MM | 2050X1500X1650 |

| weight | 1.2T | ||

Related Products